Archives: Products

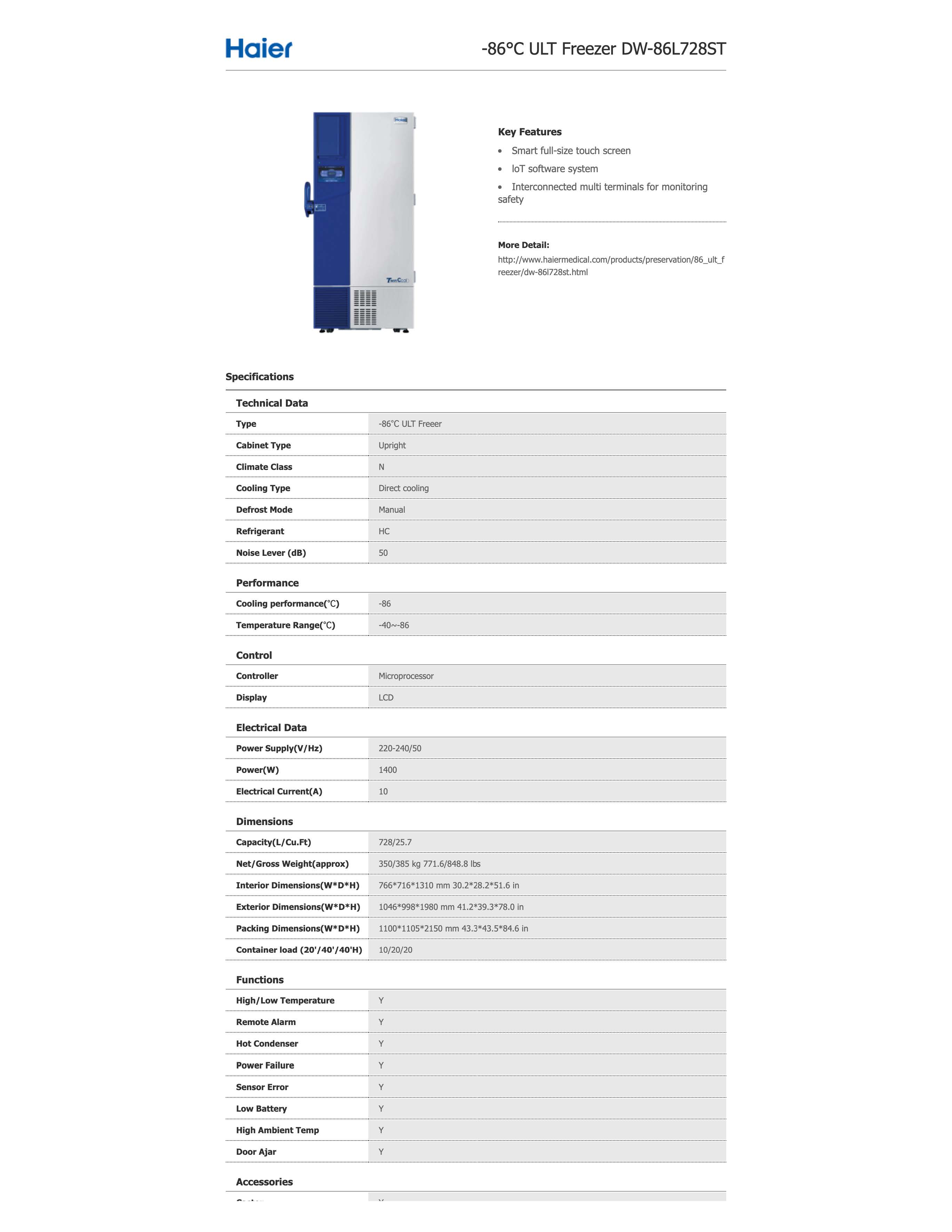

DW-86L728ST

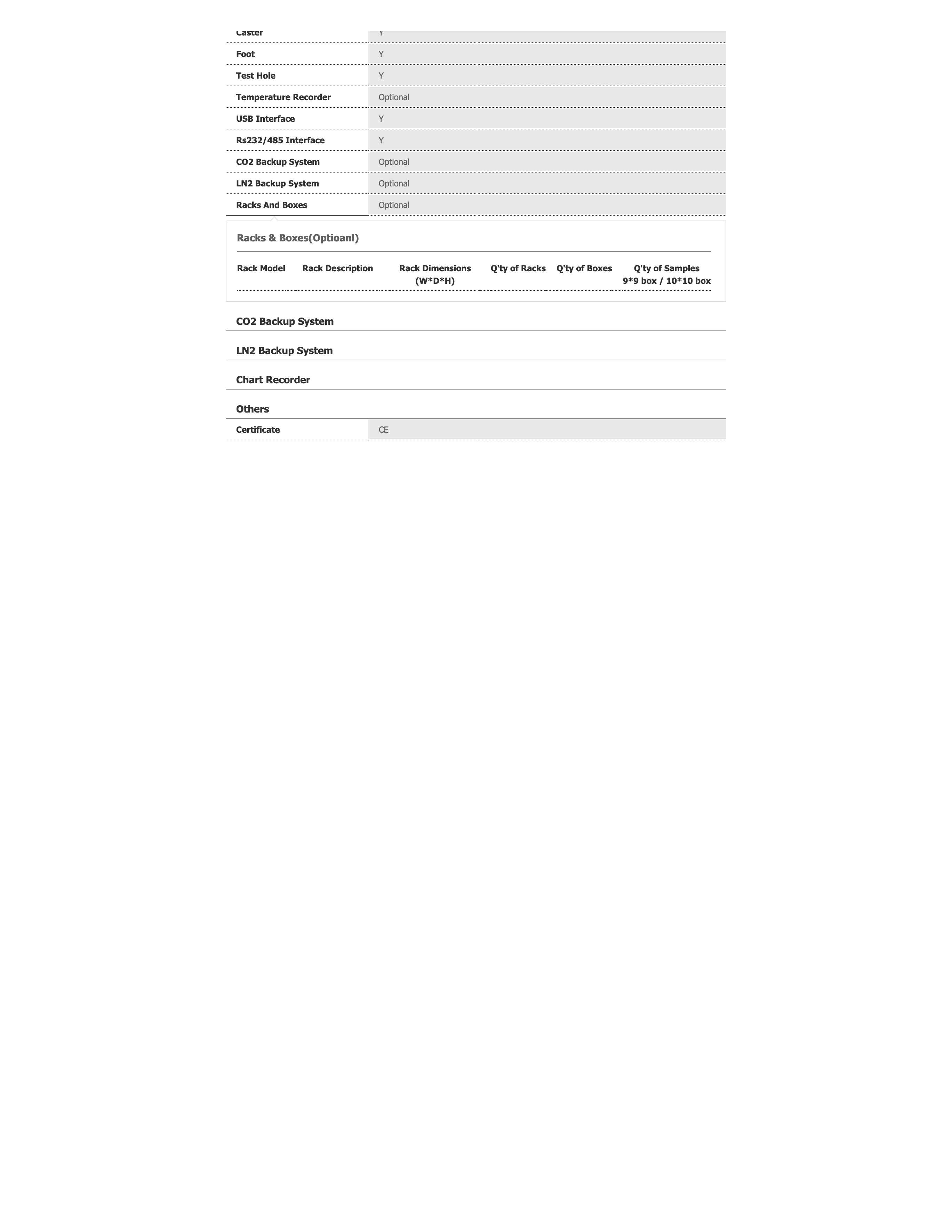

Paternoster

Fully Automatic Cryogenic Storage System

Paternoster systems are fully automated customized solutions for storage of medical, biological and chemical materials including computerized inventory system and sample picking option.[row]

Key Features:

- Closed Liquid Nitrogen (LN2) cooling system

- Cooling temperature: +4°C down to -160°C (concept and insulation dependent)

- Sample picking option

- Customized, modular turnkey solutions

- Optimization of the overall workflow

- High economic efficiency

- Modular and flexible

Advantages:

- All in one solution for storage, inventory, quality control and documentation

- GLP or MDD certification optional

- Fully computer based inventory management, password protected access

- Control and date processing via WLAN or remote access

- Easy to integrate into LIMS systems

- Space efficient

- Closed Liquid Nitrogen (LN2) cooling system

- No cross contamination of samples

- No additional air-condition necessary

- No de-icing needed

- No significant loss of temperature when loading/unloading

- Manual access even in case of power interruption

- Installation without structural alterations, parts fit through normal doors

- Alarm signal via in-house surveillance system

- Remote diagnosis and maintenance possible

- Ultra low maintenance requirement by almost any technician

- No loss of samples due to stable storage conditions

- Reduction of running cost by simplified operation

Customer Applications:

- Medicine: blood banks, transfusion medicine, pathology, …

- Pharma: plasma, stem cells, tissue, compounds, …

- Biotechnology: tissue, in vitro fertilization, …